Rotary Kiln Geometry Measurement Solutions

Comprehensive geometry measurement solutions for rotary kilns: circumferential measurement, shell ovality analysis, eccentricity detection, and precise alignment — all powered by our modular MMD system.

Why Kiln Geometry Matters

Accurate geometry measurement of rotary kilns is essential for maintaining efficient operations, preventing unplanned downtime, and extending equipment lifespan. Our modular MMD system delivers high-precision measurements for circumference, eccentricity, throw, and shell ovality — all from a single integrated platform.

Modular Design

Interchangeable sensors and upgradeable configurations — start with circumferential and expand to full geometry analysis.

High Precision

Sub-millimeter accuracy with inductive sensors ranging from 2mm to 40mm, plus laser distometer for deflection.

Wireless Connectivity

Real-time data transfer and remote monitoring capability for seamless integration with plant systems.

Extended Battery Life

4-cell 3200 mAh Li-ion battery with embedded BMS provides extended field operation time.

Geometry Measurement Capabilities

Our MMD system supports a complete range of rotary kiln geometry measurements, delivering actionable data for maintenance and alignment decisions.

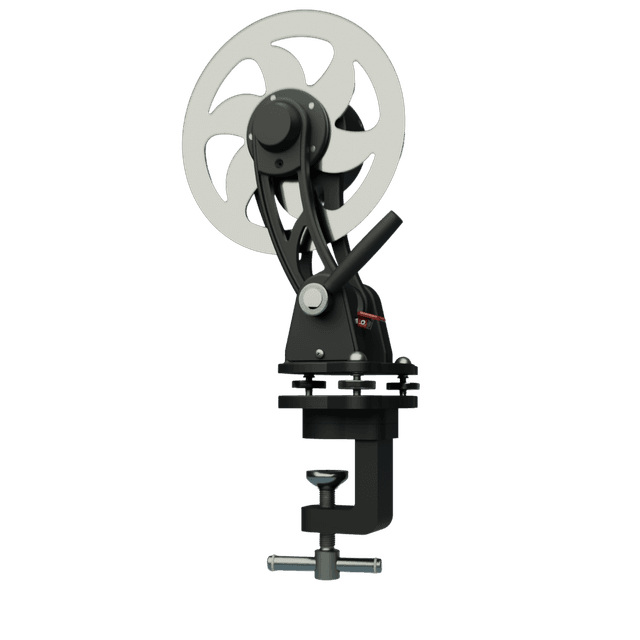

Circumferential Measurement

The measuring wheel with encoder rolls along the kiln shell surface, precisely calculating the circumference at each station. This data reveals thermal expansion patterns and helps identify hot spots or structural deformation across the kiln length.

- Measuring wheel diameter: 160 mm

- Encoder resolution: 5000 pulses per revolution

- Measurement resolution: 0.032 mm per pulse

- Reliable non-contact revolution synchronization

Eccentricity & Throw Measurement

High-precision inductive sensors detect the deviation of the kiln shell from its true center as it rotates. By measuring eccentricity and throw at each station, operators can identify misalignment, bent sections, and bearing wear before they lead to costly failures.

- Dual channel configuration (CH1 / CH2)

- Radial and axial displacement detection

- Resolution: 1–10 μm (sensor dependent)

- Real-time signal processing

Suitable for

Laser Distance Measurement

A non-contact laser distance sensor measures surface displacement with high repeatability, making it ideal for harsh environments where physical sensor contact is not feasible. It accurately captures deflection and throw data at every station.

- Working range: 60–210 mm

- Non-contact surface displacement measurement

- Repeatable detection of deflection & throw

- Real-time visualization via PC software

Used where

Precision Sensors & Equipment

Each sensor in the MMD ecosystem is engineered for harsh industrial environments — heat-resistant, vibration-tolerant, and built for repeatable accuracy.

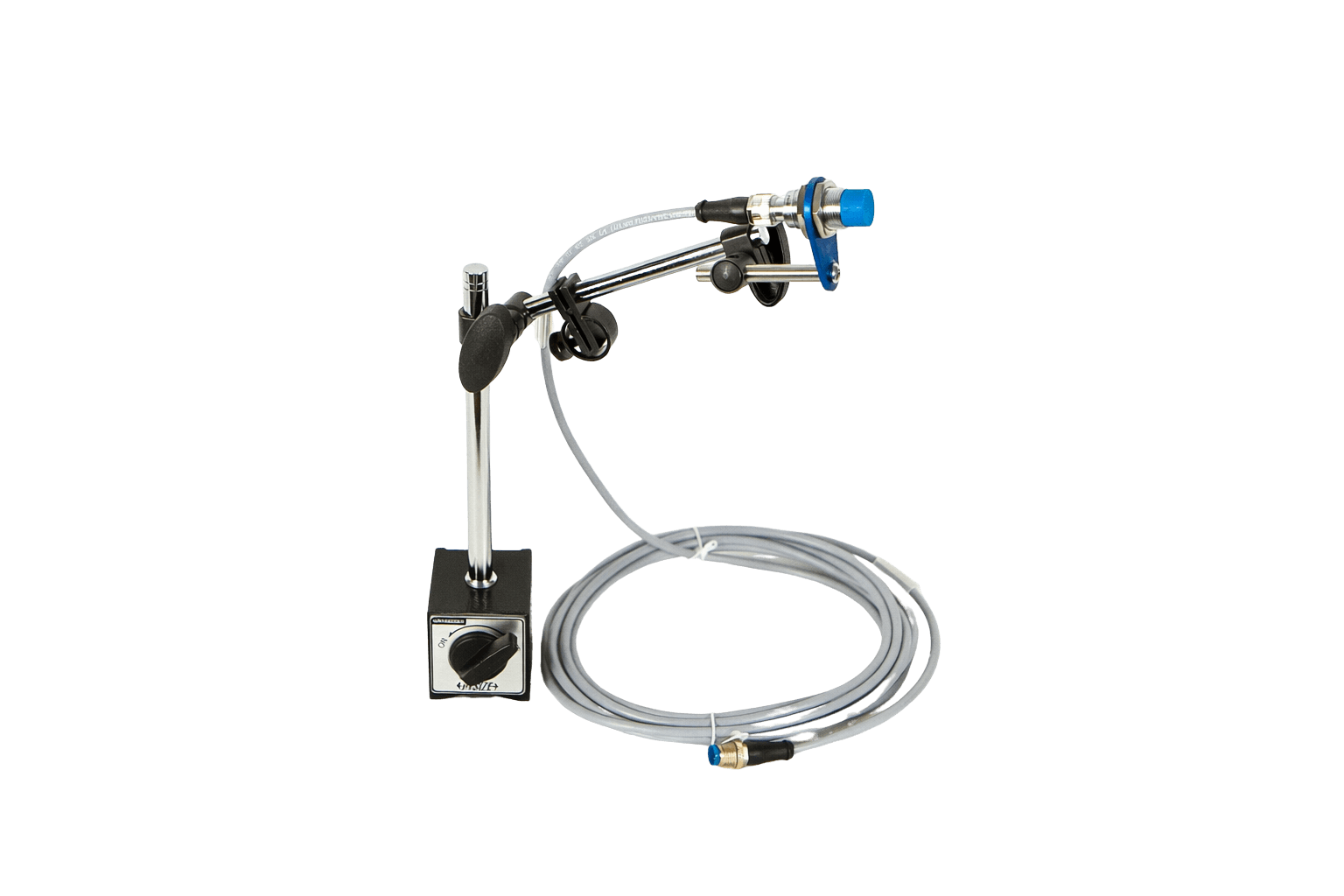

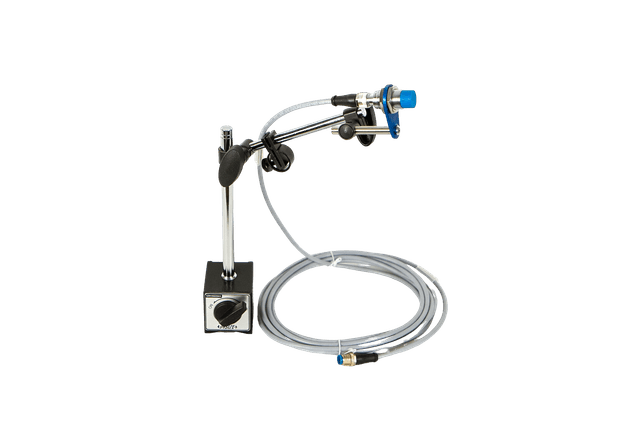

Inductive Sensors

High-precision SICK IMA and Baumer inductive sensors in 4 ranges (2–5mm, 0–10mm, 0–20mm, 0–40mm) for eccentricity, throw, and ovality measurements on magnetic mounting stands.

Laser Distometer

Laser-based displacement sensor with 60–200mm range for non-contact shell deflection and ovality measurements. Ideal for applications where sensor proximity to hot surfaces is limited.

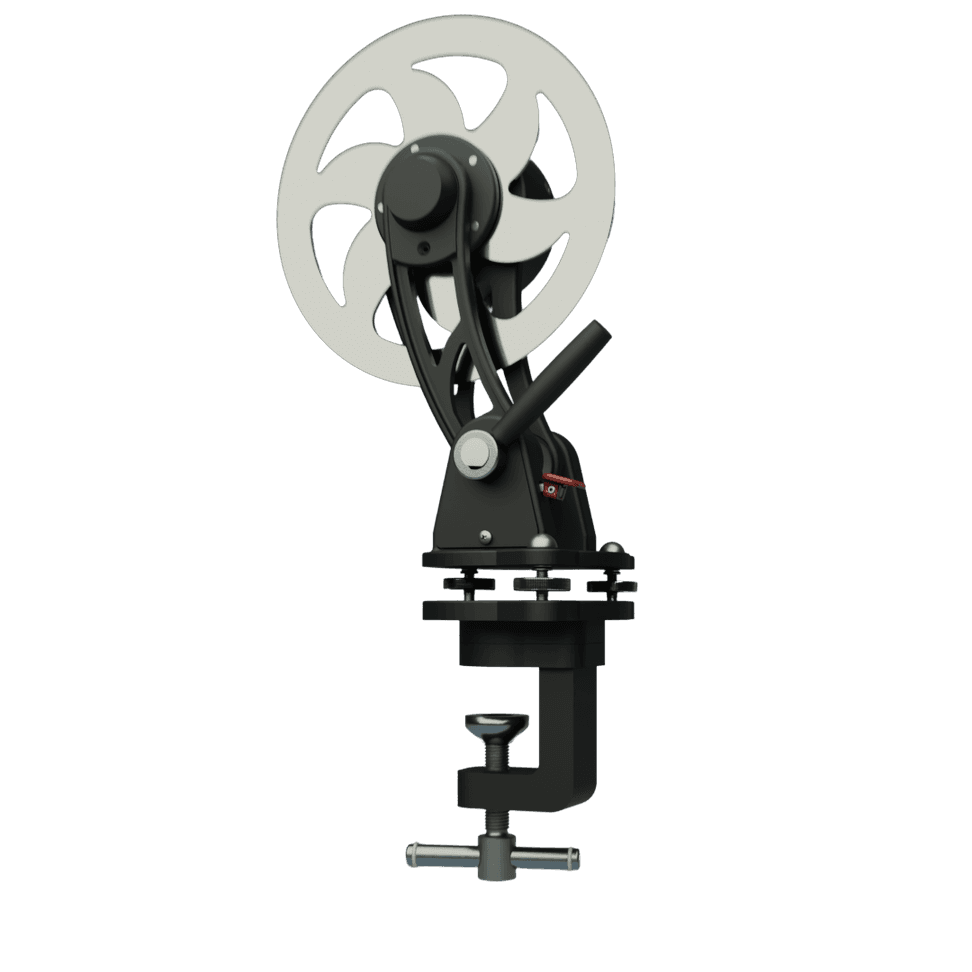

Measuring Wheel

Precision encoder wheel designed for circumferential measurement of large, slow-rotating cylinders. Contact-based measurement delivers reliable circumference data across all kiln stations.

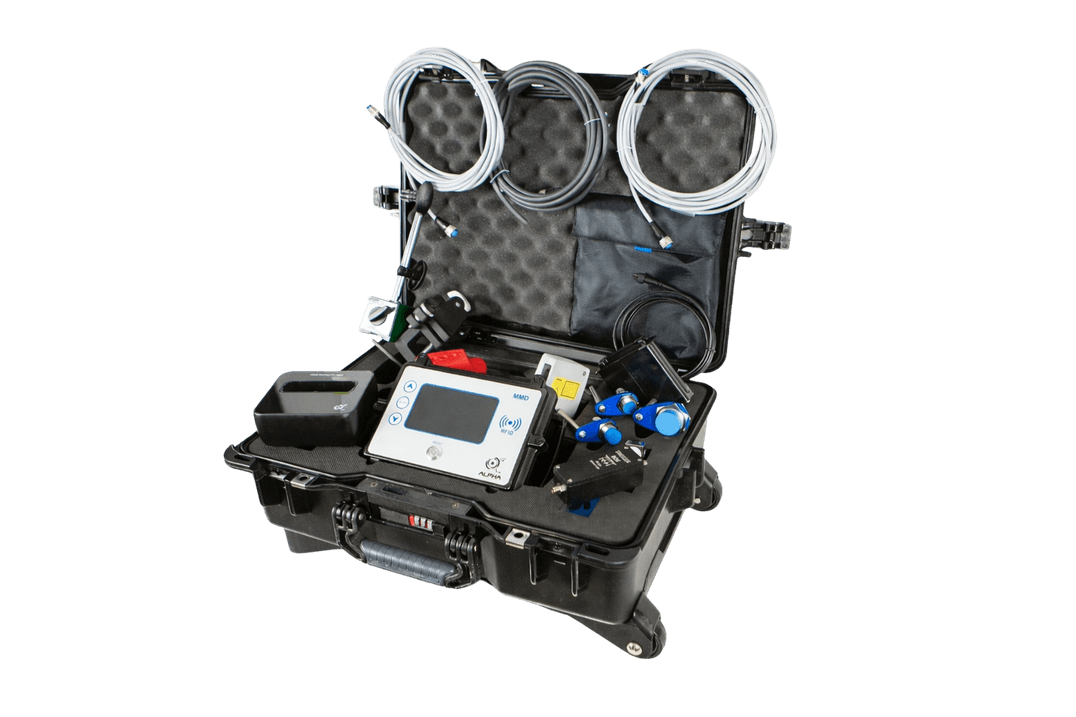

Complete Field System

Every MMD kit ships in a rugged carrying case with all the tools, sensors, and accessories needed for comprehensive field measurement. Simply choose your configuration — Circumferential, Advanced, or Combo — and you are ready to measure.

- MMD Box with 32-bit ARM Cortex-M4 core and 4.3" display

- Configurable sensor package (inductive, laser, wheel)

- Patented contactless trigger sensor for precise rotation tracking

- Temperature-resistant silicone magnet flags

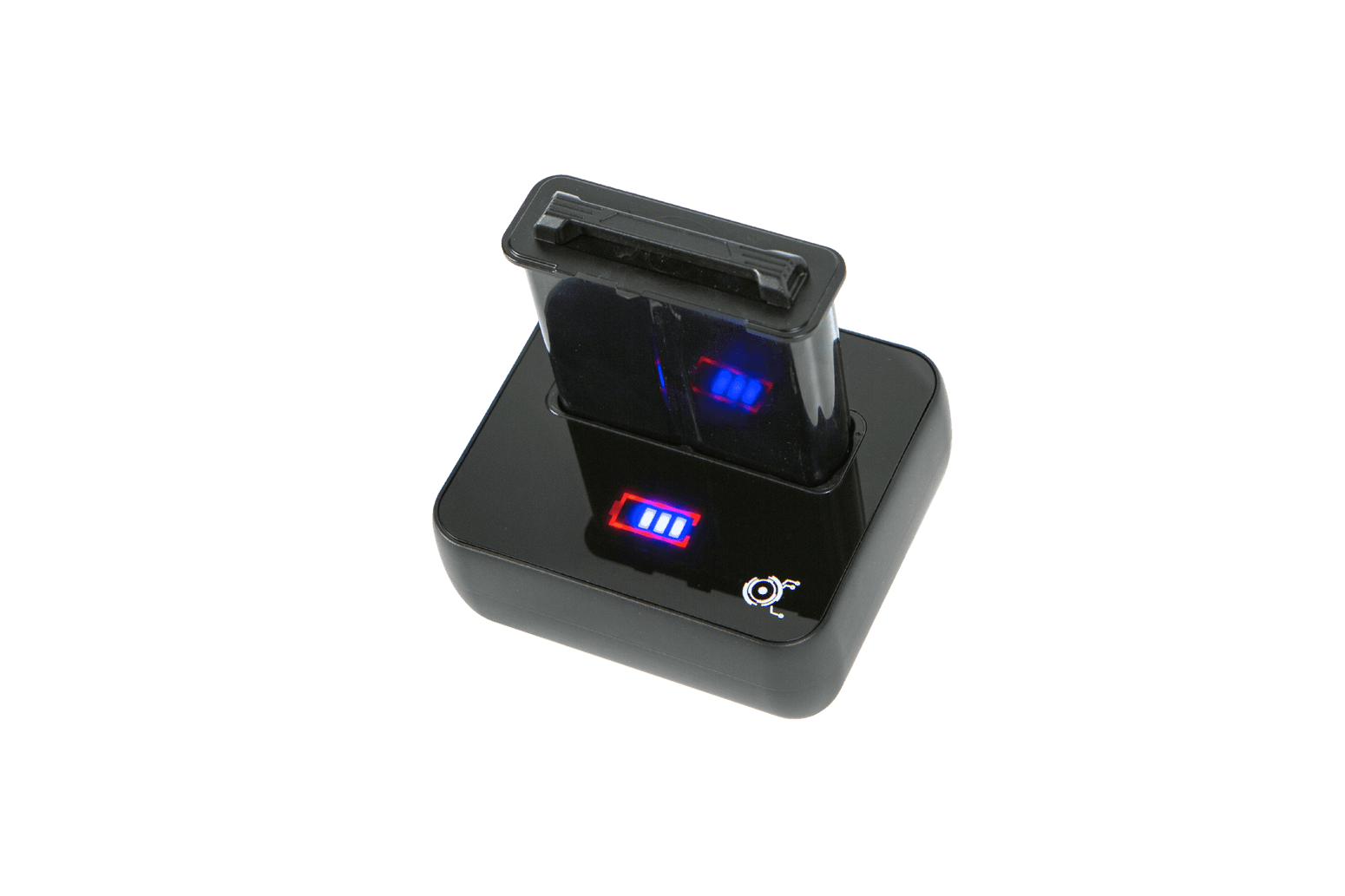

- Dedicated battery charger with LED level indicator

- Li-ion battery pack with embedded BMS

- USB and 19VDC connectivity

- Magnetic mounting hardware and cables

Battery & Connectivity

Designed for extended field use, the MMD battery system ensures uninterrupted measurement sessions. The dedicated charger with LED indicator makes power management simple and reliable.

CE & RoHS Certified

All MMD devices meet European safety and environmental standards.

Engineered by Alpha Teknoloji

R&D-driven solutions from Ankara, Turkey — trusted globally.

Ready to Get Started?

Choose the MMD configuration that fits your measurement needs. Whether you need circumferential-only or complete geometry analysis, we have the right solution for you.